Adjusting a pusher feeder focuses on optimizing mechanical stroke, timing, and sensor feedback. Mechanical Adjustment Inspection & Cleaning Safety: Disconnect air and power. Action: Clean and check for wear on the pusher, guides, and hopper. Adjust Pusher Stroke Goal: Ensure the pusher fully ejects the part without over-travel. Method: For Pneumatic Cylinders: Adjust sensor positions or flow control valves. […]

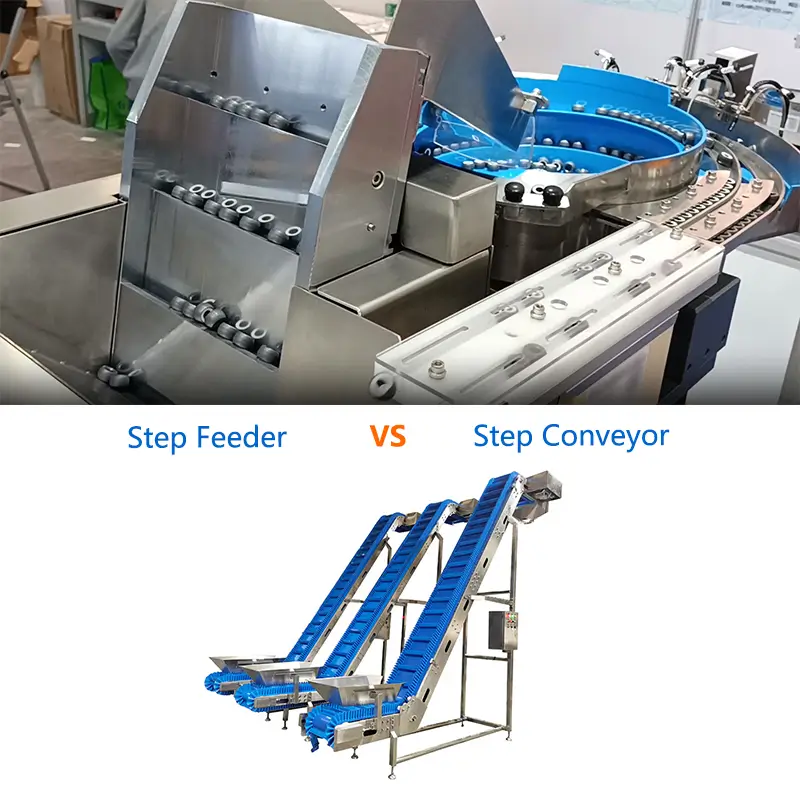

Arquivos de Categoria: Step Feeder

The working principle of a step feeder can be summarized in three core steps, forming a typical “push-return-wait” cycle: Reset and Loading Process: The pusher is in its retracted home position. Parts in the hopper fall by gravity to fill the space in front of the pusher. Purpose: Prepares parts for the next feeding cycle. Advancing and […]

The manufacturing of a step feeder focuses on creating a precise, reliable, and linear feeding mechanism tailored to specific parts. Part Analysis and Hopper Design Analysis: Precisely measure the part and analyze its behavior when stacked to design a hopper that prevents jamming and misorientation. Hopper Design: The hopper is custom-designed to match the part’s […]