1. Introduction

Qu'est-ce qu'un alimentateur vibrant avec trémie ?

Définir et introduire les alimentateurs vibrants avec trémies.

2. Comment ça marche ?

Mécanisme de base des alimentateurs vibrants

Aperçu des principes de fonctionnement du chargeur.

3. Avantages des bols vibrants avec trémies

Efficacité améliorée

Discutez des améliorations d’efficacité.

Flux de matériaux constant

Mettre en évidence les avantages du maintien d’un flux uniforme.

Polyvalence dans tous les secteurs d'activité

Citez diverses applications dans divers secteurs industriels.

4. Types d'alimentateurs vibrants avec trémies

Modèles standards

Décrivez les conceptions standard d’alimentateur et de trémie.

Configurations personnalisables

Expliquez comment les conceptions peuvent être personnalisées.

5. Applications

Industrie automobile

Explorez les utilisations spécifiques dans la fabrication automobile.

Transformation des plastiques et des métaux

Discutez de son rôle dans la manutention des matériaux.

Établissements d'enseignement

Adressez l'utilisation du chargeur dans les laboratoires de recherche ou de formation.

6. Considérations relatives à la conception

Choisir la bonne capacité

Facteurs déterminant la taille de la trémie et du chargeur.

Compatibilité des matériaux

Importance de l'adéquation des matériaux avec la conception du chargeur.

7. Conseils d'entretien

Inspections de routine

Mettez en évidence les pratiques de maintenance pour éviter les temps d’arrêt.

Dépannage des problèmes courants

Fournir des conseils pour résoudre les problèmes fréquents.

8. Pourquoi investir dans des bols vibrants avec trémies ?

Rentabilité

mettre l’accent sur l’épargne à long terme.

Fiabilité

Discutez de la cohérence des performances au fil du temps.

9. Les solutions de SWOER

Notre expertise

Présentez l’expertise et les offres de SWOER.

Pourquoi choisir SWOER?

Mettre en valeur les avantages concurrentiels.

10. Conclusion

Réflexions finales

1. Introduction

Qu'est-ce qu'un alimentateur vibrant avec trémie ?

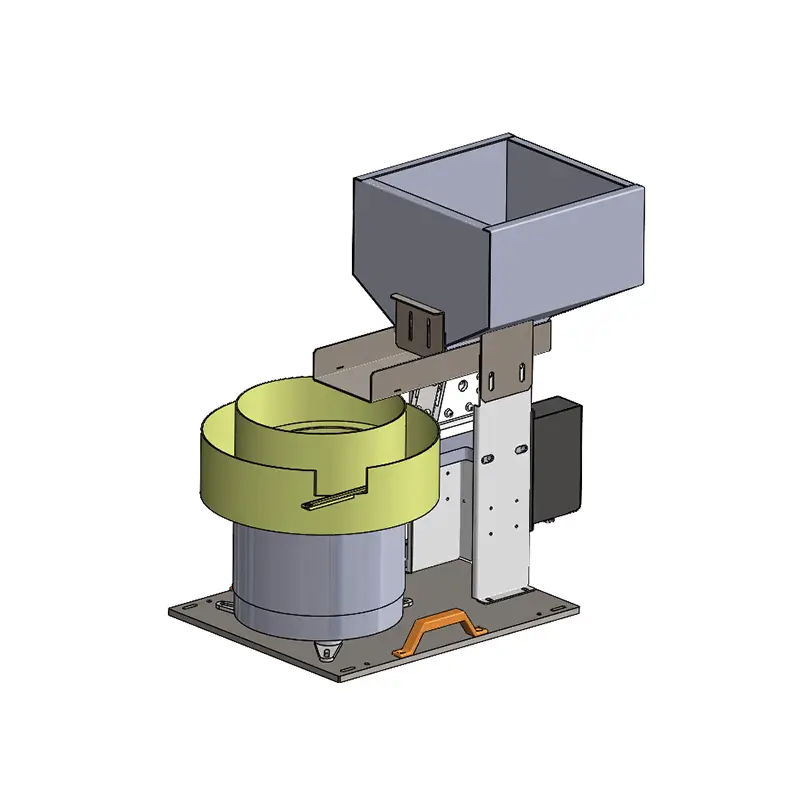

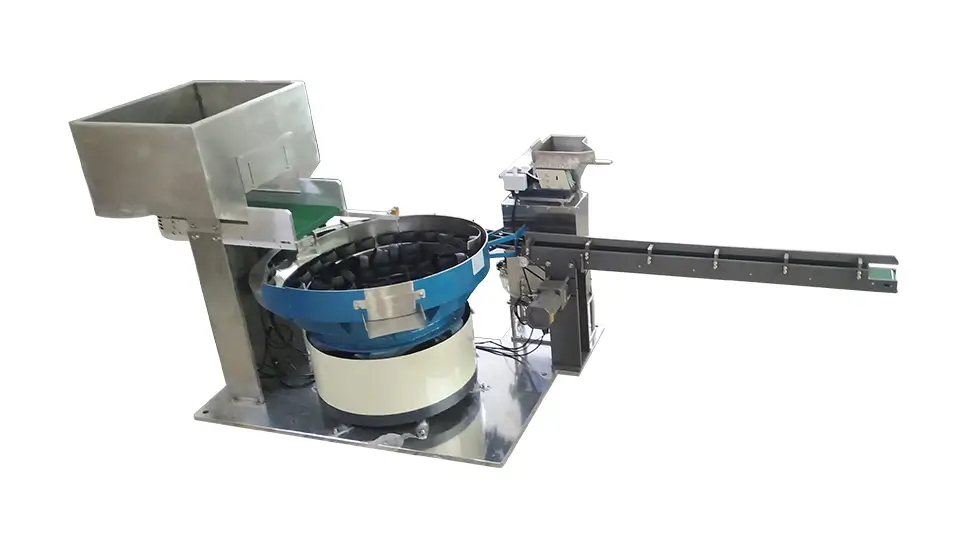

Imaginez une machine qui fonctionne comme un service de livraison parfaitement synchronisé, garantissant que chaque article arrive au bon endroit, dans la bonne orientation, juste au moment où il est nécessaire. C'est exactement ce que fait un bol vibrant avec trémie. Ces dispositifs font partie intégrante de l'automatisation, combinant une mangeoire à bolLes capacités de tri précises d'un système de tri combiné à la capacité de stockage d'une trémie. Ensemble, ils rationalisent la production, évitent les temps d'arrêt et assurent le bon déroulement des opérations.

2. Comment ça marche ?

Mécanisme de base des alimentateurs vibrants

Bols vibrants Les vibrations permettent de déplacer les pièces sur un trajet contrôlé. C'est comme secouer une boîte de chocolats : un petit coup de pouce suffit pour que tout se déroule sans accroc. La piste en spirale du bol garantit que les pièces sont correctement orientées lorsqu'elles se déplacent vers le point de sortie.

Rôle de la trémie

Une trémie fait office d'assistante fidèle du doseur. Elle stocke et distribue le matériau dans le bol doseur, assurant ainsi un approvisionnement constant. Sans trémie, vous devrez remplir manuellement le doseur, ce qui vous fera perdre du temps et risquera d'entraîner un flux irrégulier. Les trémies peuvent traiter des matériaux en vrac et les alimenter progressivement, comme si vous versiez juste assez de grains de café dans votre moulin sans le surcharger.

3. Avantages des trémies vibrantes

Efficacité améliorée

Le temps, c'est de l'argent dans des secteurs comme l'automobile et la transformation des matières plastiques. Une trémie d'alimentation vibrante élimine les goulots d'étranglement, permettant aux lignes de production de fonctionner sans interruption pour les remplissages manuels. L'efficacité monte en flèche lorsque les machines effectuent le travail que les humains faisaient auparavant.

Flux de matériaux constant

Imaginez que vous essayez de verser du sucre dans un petit entonnoir sans en renverser. C'est compliqué, n'est-ce pas ? Une trémie garantit que la bonne quantité de matière s'écoule de manière constante dans le doseur, évitant ainsi les surtensions ou la famine. Ce fonctionnement fluide améliore la productivité.

Polyvalence dans tous les secteurs d'activité

Qu'il s'agisse d'alimenter des vis dans une chaîne de montage, de manipuler des granulés de plastique dans un atelier de fabrication ou de démontrer des principes d'automatisation dans une salle de classe, ces appareils trouvent leur place dans divers secteurs. Leur adaptabilité est sans égale.

4. Types d'alimentateurs vibrants avec trémies

Modèles standards

Les doseurs standards avec trémies répondent à la plupart des besoins industriels. Ils sont robustes, fiables et parfaits pour la manutention de matériaux uniformes.

Configurations personnalisables

Besoin d'un alimentateur pour des articles délicats comme des flacons en verre ou des composants lourds comme des boulons ? Les conceptions personnalisables s'adaptent aux exigences uniques, garantissant un fonctionnement sans faille pour n'importe quel matériau.

5. Applications

Industrie automobile

Pensez aux lignes d'assemblage de voitures : les vis, les fixations et les autres composants doivent être alimentés avec précision et rapidité. Les alimentateurs vibrants avec trémies sont parfaits ici, car ils garantissent que chaque pièce arrive à destination parfaitement orientée.

Transformation des plastiques et des métaux

Du moulage par injection à l’extrusion, ces alimentateurs manipulent les matières premières avec facilité, en maintenant des flux de production constants.

Établissements d'enseignement

Les laboratoires de recherche et les écoles d'ingénieurs utilisent ces alimentateurs pour enseigner les principes d'automatisation et de manutention. Ce sont des outils d'apprentissage petits mais puissants.

6. Considérations relatives à la conception

Choisir la bonne capacité

La taille de la trémie et la capacité du dispositif d'alimentation dépendent du volume de votre matériau et de votre vitesse de production. Les trémies surdimensionnées gaspillent de l'espace, tandis que les trémies sous-dimensionnées entraînent des retards. Adaptez la conception à votre charge de travail pour des résultats optimaux.

Compatibilité des matériaux

Vous utilisez des matériaux abrasifs ? Optez pour un distributeur doté de surfaces résistantes. Vous manipulez des objets délicats ? Les revêtements souples sont votre meilleur choix. La conception et la compatibilité des matériaux vont de pair.

7. Conseils d'entretien

Inspections de routine

Des contrôles réguliers permettent à votre mangeoire de fonctionner comme un rêve. Vérifiez l'usure, assurez-vous que les boulons sont bien serrés et nettoyez les surfaces pour éviter toute obstruction.

Dépannage des problèmes courants

Le chargeur ne vibre pas ? Vérifiez l'alimentation électrique. Le matériau est coincé ? Inspectez la sortie de la trémie. Connaître ces solutions peut vous faire gagner un temps d'arrêt précieux.

8. Pourquoi investir dans des bols vibrants avec trémies ?

Rentabilité

Même si le coût initial peut sembler élevé, les économies de main-d’œuvre à long terme et la productivité accrue font de ces appareils un investissement judicieux.

Fiabilité

Contrairement aux humains, les machines ne se fatiguent pas et n'ont pas besoin de pauses. Les bols vibrants avec trémies offrent des performances constantes, poste après poste.

9. Les solutions de SWOER

Notre expertise

À SWOER, nous avons passé plus d'une décennie à perfectionner les alimentateurs et trémies vibrants. Nos conceptions combinent précision, durabilité et personnalisation pour répondre à tous les besoins industriels.

Pourquoi choisir SWOER?

En tant que l'un des principaux fabricants chinois, nous offrons une qualité et un service inégalés. De la consultation initiale au support après-vente, SWOER vous couvre.

10. Conclusion

Réflexions finales

Les trémies vibrantes sont les héros méconnus de la production moderne. Elles permettent de gagner du temps, d'augmenter l'efficacité et de s'adapter à presque toutes les tâches. Que vous soyez dans la fabrication automobile, la transformation des matières plastiques ou l'éducation, investir dans ces appareils est une évidence. Prêt à rationaliser vos opérations ? Contactez SWOER dès aujourd'hui !