Which Springs Are Suitable for Vibratory Bowls?

In general, the vast majority of springs are highly unsuitable for traditional vibratory bowls. The working principle of a vibratory bowl (vibration and friction) directly conflicts with the physical properties of springs (prone to tangling and deformation).

However, under very limited conditions, certain types of springs can be used with difficulty, but it is generally not recommended.

Spring Types That Are Almost Always Unsuitable:

Compression Springs (Especially those with a high slenderness ratio)

Reason: During vibration, they will twist and tangle with each other into impossible knots, making separation unfeasible.

Extension Springs

Reason: The hooks on both ends will readily catch onto other springs, instantly forming a tangled clump.

Torsion Springs

Reason: The complex shape and protruding arms cause them to easily interlock.

Conical Springs

Reason: They nest inside each other, becoming tightly stuck and inseparable.

Spring Types That Might Be Feasible Under Specific Conditions:

If your spring meets ALL of the following criteria, you can attempt to use a specially designed bowl:

Short and Stout Compression Springs

Descripción: Very short in length with a large diameter, resembling a “washer” shape (slenderness ratio close to 1).

Reason: This shape significantly reduces the potential for tangling and is relatively stable on the track.

Spiral/Wave Springs

Descripción: Flat in shape, multiple springs do not hook into each other.

Reason: They behave more like washers, sliding on the track rather than rolling or hooking.

Small Spring Washers

Descripción: Although a spring, its shape is an open ring and can often be fed similar to a standard washer.

Reason: The bowl track can be designed to maintain its orientation (open side up or down).

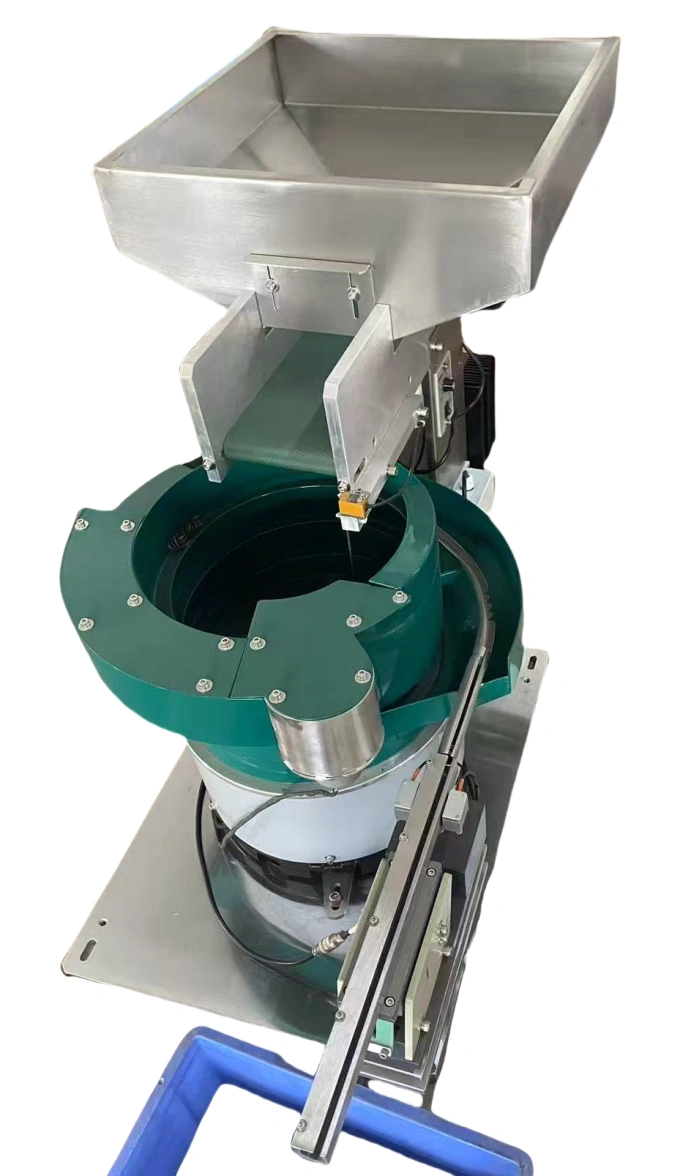

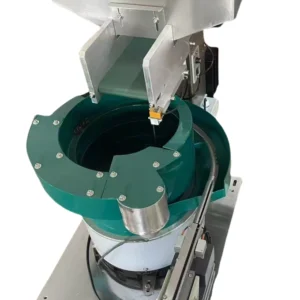

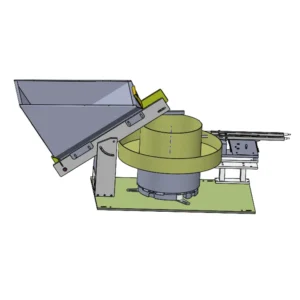

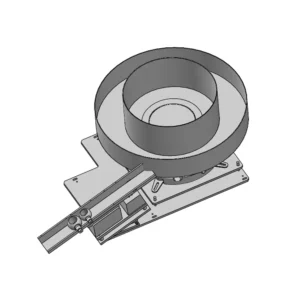

Even for the “feasible” springs mentioned above, the vibratory bowl requires special design:

Extremely Low Material Level: To prevent excessive contact between springs.

Non-Stick Coating (e.g., Teflon): To reduce friction and static electricity.

Highly Optimized Track: With covers or special guiding tools to prevent springs from standing up or tilting.

Possible Air Assistance: To help propel and orient them.

Recommended Alternative Solutions

For spring feeding, the modern automation industry strongly prefers non-vibratory solutions, which are truly suitable for springs:

Alimentadores de pasos

Principle: A linear pusher gently separates and pushes springs one by one from a magazine.

Ventaja: Completely eliminates tangling, is gentle on springs, quiet, and reliable. This is the primary recommended solution for spring feeding.

Flexible Feeders with Vision Systems

Principle: A robot grabs a handful of springs from a bulk box and scatters them onto a flexible feeder. A vision system identifies correctly oriented springs and guides the robot to pick them.

Ventaja: Solves the tangling problem at its root and allows for extremely easy product changeover, suitable for low-volume, high-mix production.

Reseñas

No hay ninguna reseña todavía.