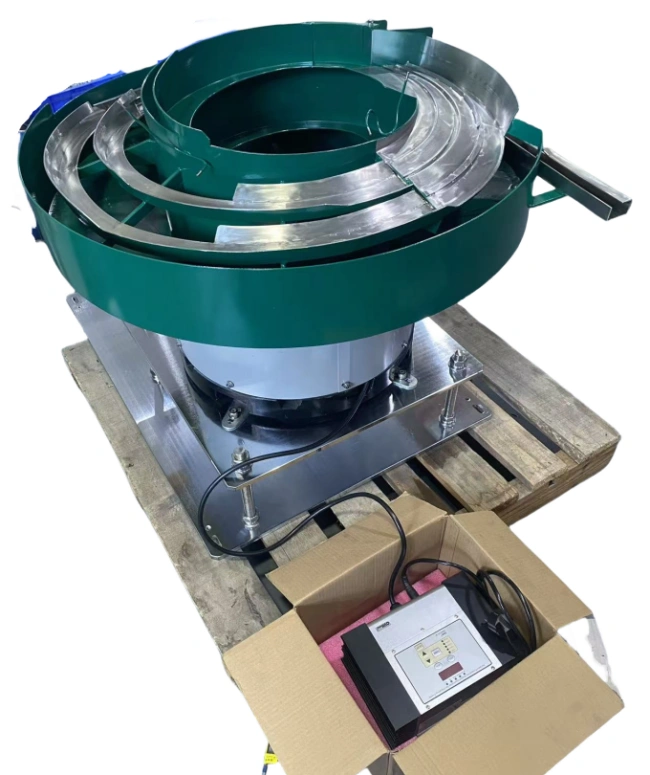

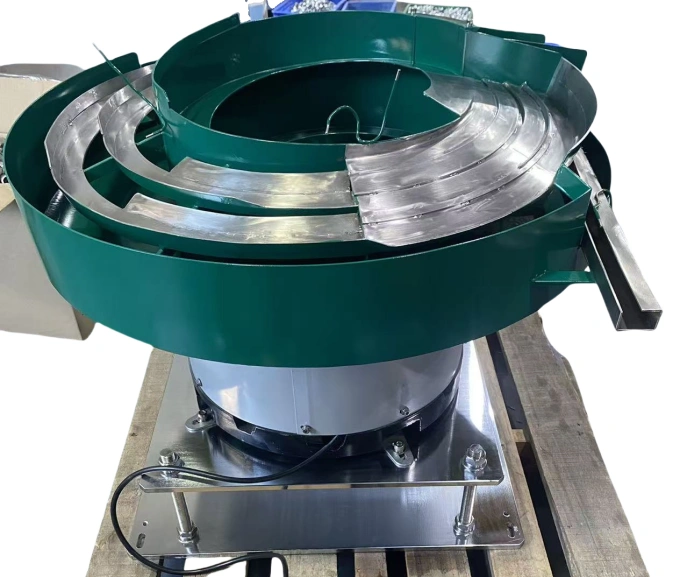

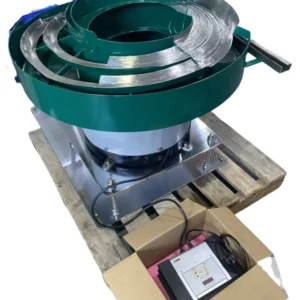

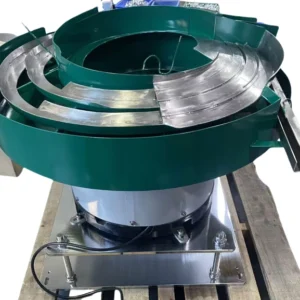

Benefits of a Vibratory Bowl with Parting/Separating Structures

Integrating parting structures is a core engineering optimization that delivers multiple critical benefits:

- Enhanced Feeding Reliability and Stability

- Prevents Jams: Proactively removes overlapping, upright, or misoriented parts, eliminating the primary cause of stoppages.

- Ensures Consistent Output: Guarantees every discharged part is in the predetermined correct orientation, providing a reliable foundation for downstream automation.

- Achieves Near-100% Orientation Accuracy

- Precise Sorting: Structures perform complex logic, e.g., allowing only head-up screws or washers facing a specific direction to pass.

- Result: Upgrades probabilistic sorting to deterministic output, drastically reducing assembly errors or machine damage from wrong part orientation.

- Increases Production and Overall Equipment Efficiency

- Reduces Downtime: Minimizes unplanned stops by preventing jams and backflow.

- Synchronizes Pace: Metering gates control output to perfectly match the cycle time of downstream robots or machines.

- Enables Distribution: Multi-way diverters feed parts to multiple stations for parallel processing, maximizing utilization.

- Reduces Stringent Requirements for Part Consistency

- Robust Design: Well-designed structures can tolerate minor part variations like burrs or light oil, improving system robustness.

- Extends Equipment Life

- Reduces Abnormal Wear: Prevents excessive friction and impact caused by jamming, reducing wear on the bowl and track.

- Elevates the Intelligence of the Automation Line

- Adjustability: Some structures are tunable for different products, increasing flexibility.

- Enables Advanced Processes: A stable, well-oriented part stream is essential for implementing vision inspection and robotic picking.

Summary: Parting structures represent the key evolution of a vibratory bowl from merely “functional” to efficient, reliable, and intelligent. Through active mechanical intervention, they transform a chaotic stream of parts into a stable, pure, and precise flow. Their value is directly reflected in increased uptime, higher product quality, and lower total cost of operation.

Reseñas

No hay ninguna reseña todavía.