The speed of a vibratory bowl is typically measured in parts per minute (PPM). It’s a complex performance metric influenced by several factors.

- Speed Range

- General Range: For small, standard parts, well-designed bowls can achieve speeds from dozens to hundreds of PPM.

- High-Speed: In optimized scenarios, speeds can exceed 1000 PPM.

- Low-Speed: For delicate or complex parts, speed is often reduced for stability.

- Key Factors Influencing Speed

- Part Characteristics

- Size & Weight: Smaller, lighter parts can be fed faster.

- Shape Complexity: Simple, uniform shapes allow for higher speeds.

- Surface Friction: Smooth parts flow more freely.

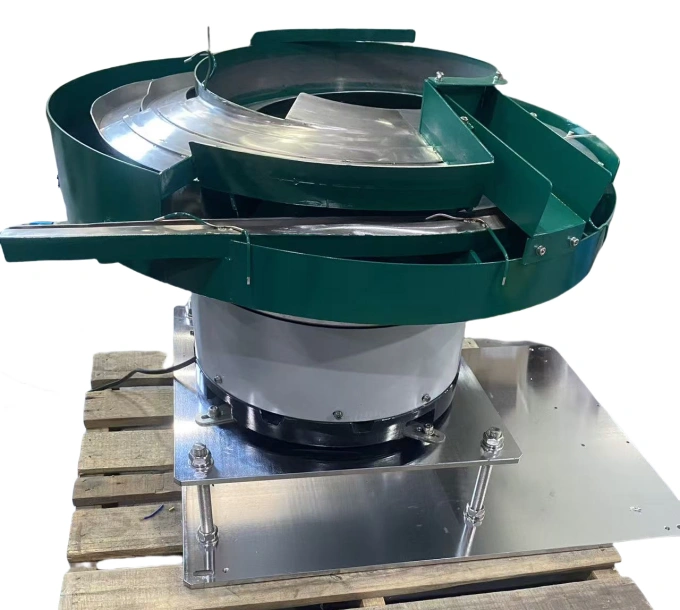

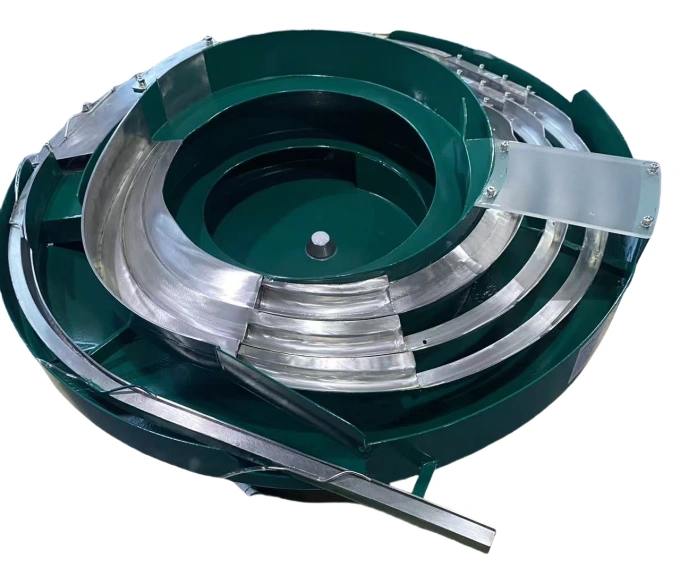

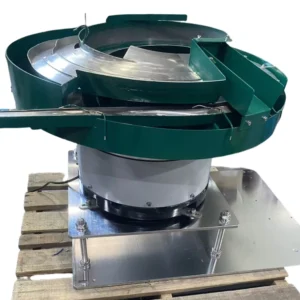

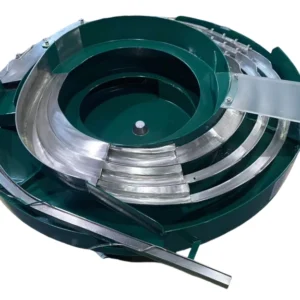

- Bowl Design & Condition

- Track Design: Impacts flow efficiency.

- Vibration Tuning: Amplitude y frequency must be precisely tuned.

- Surface Treatment: Low-friction coatings can increase speed.

- Maintenance: Wear and cleanliness affect performance.

- Application Requirements

- Orientation Accuracy: 100% accuracy may require a slight speed reduction.

- Stability: A consistent, moderate speed is often more efficient than an unstable high speed.

III. How to Gauge Speed?

“Bowl speed” involves two concepts:

- Transport Speed: How fast parts move on the track.

- Output Efficiency: The rate of correctly oriented parts delivered. This is the most critical speed for production.

In summary, while vibratory bowls can achieve high speeds, the ultimate goal is effective and stable output speed. It represents a balance between part characteristics, design quality, and stability requirements.**

Final advice: Always provide samples and your target efficiency to your supplier for a bowl that best meets your needs for both speed and stability.

Reseñas

No hay ninguna reseña todavía.