Контур

- Обзор устройств подачи деталей в промышленной автоматизации.

- Значение в сборочных линиях и производственных процессах.

- Определение и основная функция.

- Типы питателей деталей: введение.

А. Вибрационные питатели

- Пояснение к вибрационным питателям.

- Распространенные области применения и преимущества.

B. Вибрационные чашечные питатели

- Описание вибропитателей.

- Как они сортируют и ориентируют детали.

C. Другие типы кормушек

- Краткое упоминание о центробежных и шаговых питателях.

- Автоматизированная индустрия

- Роль вибропитателей в сборке автомобилей.

- Производство электроники

- Важность при работе с мелкими компонентами.

- Фармацевтическая индустрия

- Используется при упаковке и дозировании.

- Повышение эффективности и производительности.

- Сокращение ручного труда и ошибок.

- Последовательная ориентация и поставка деталей.

- Ключевые соображения при выборе производителей.

- Важность индивидуальных решений.

- Обзор значения устройств подачи деталей в современном производстве.

- Какова основная функция вибрационного питателя?

- Как работает вибрационный питатель?

- В каких отраслях промышленности обычно используются устройства подачи деталей?

- Могут ли вибропитатели работать с хрупкими деталями?

- Как выбрать подходящий для моей сферы применения фидер деталей?

I. Введение

В сфере промышленной автоматизации питатели деталей играют ключевую роль в оптимизации процессов сборки. Эти устройства эффективно транспортируют и сортируют компоненты, обеспечивая плавный рабочий процесс в различных производственных условиях. Поскольку отрасли все больше полагаются на автоматизацию, понимание функций и типов питателей деталей, в частности вибрационных питателей и вибропитателей, становится необходимым для оптимизации производственных линий. В этой статье рассматриваются различные аспекты питателей деталей, подчеркивается их значение, области применения и соображения при выборе производителя.

II. Что такое устройство подачи деталей?

Питатели деталей — это автоматизированные системы, предназначенные для обработки больших объемов компонентов, доставляя их по одному в определенной ориентации в указанное место в производственной среде. Их основная функция — эффективно перемещать детали, обеспечивая при этом их правильную ориентацию для последующей обработки. За счет сокращения ручного труда питатели деталей значительно повышают эффективность производства, что делает их незаменимыми на современных сборочных линиях.

Существуют различные типы питателей деталей, каждый из которых предназначен для определенных применений и требований. Среди них наиболее распространены вибрационные питатели и вибрационные чашечные питатели, предлагающие уникальные преимущества, которые подходят для различных отраслей промышленности.

III. Типы питателей деталей

А. Вибрационные питатели

Вибрационные питатели используют вибрацию для перемещения деталей по траектории, обеспечивая постоянный и контролируемый поток. Они универсальны и могут обрабатывать широкий спектр материалов, от небольших винтов до более крупных компонентов. Непрерывное движение и регулируемые настройки вибрации позволяют производителям настраивать скорость подачи в соответствии со своими потребностями. К распространенным областям применения относится подача компонентов в процессах сборки и упаковки автомобилей.

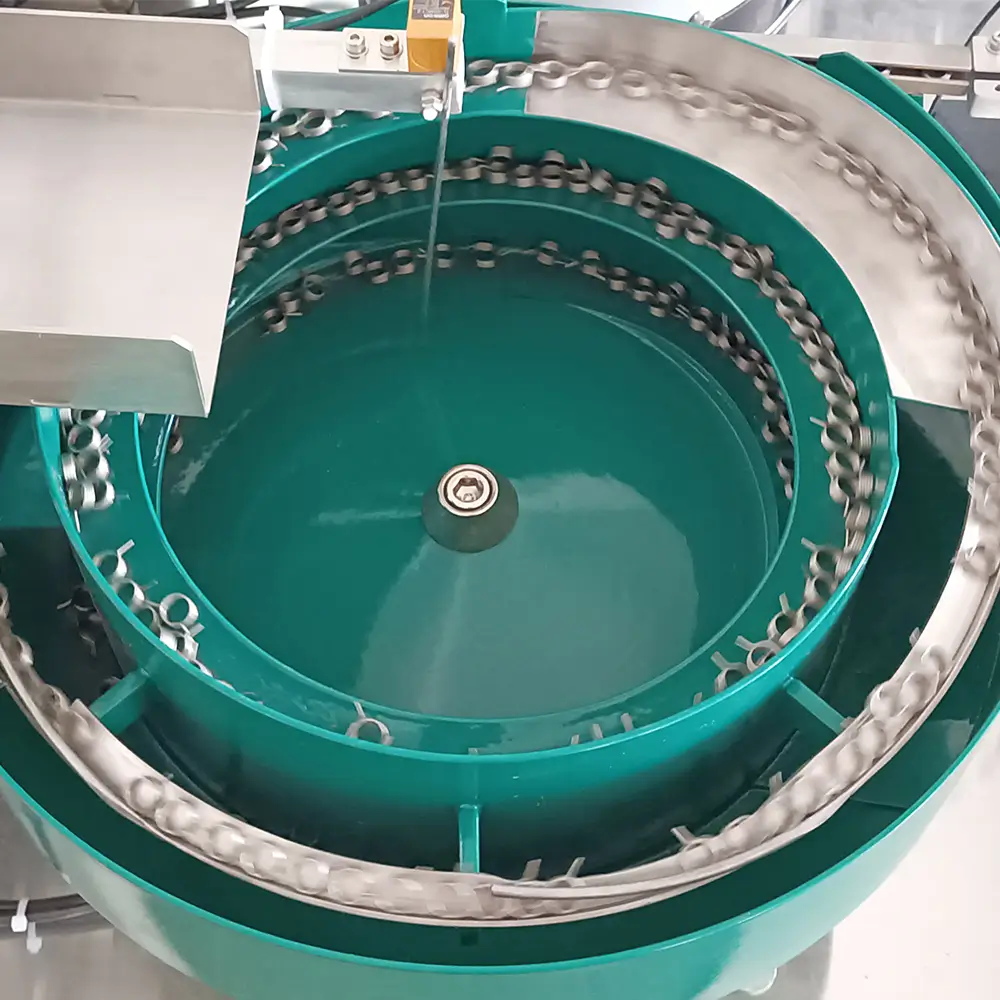

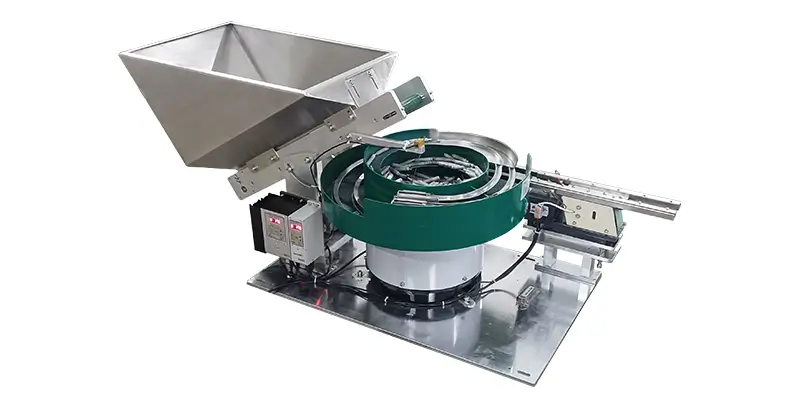

B. Вибрационные чашечные питатели

Вибрационные чашечные питатели являются специализированным типом вибрационного питателя. Они состоят из чашеобразного контейнера, который вибрирует для ориентации и подачи деталей в одном направлении. Такая конструкция особенно эффективна для небольших сложных компонентов, требующих точной ориентации. Используя комбинацию вибрации и гравитации, вибрационные чашечные питатели могут эффективно сортировать и доставлять детали, что делает их популярным выбором в таких отраслях, как электроника и фармацевтика.

C. Другие типы кормушек

Хотя вибрационные и чашечные питатели получили наибольшее распространение, другие типы питателей также играют определенную роль в автоматизации. Центробежные питатели, например, использовать вращательное движение для подачи деталей, в то время как шаговые кормушки обеспечивают вертикальный подъемный механизм. Каждый тип имеет свои уникальные области применения и преимущества, что позволяет производителям выбирать лучшее решение для своих конкретных потребностей.

IV. Применение питателей деталей

А. Автомобильная промышленность

В автомобильной промышленности вибрационные питатели необходимы для обработки различных компонентов во время сборки. Они оптимизируют процессы, гарантируя подачу деталей в правильной ориентации и с правильной скоростью, что имеет решающее значение для поддержания производительности и сокращения времени сборки.

Б. Производство электроники

Производители электроники широко используют вибрационные питатели для облегчения обработки небольших, деликатных компонентов, таких как печатные платы и разъемы. Их способность управлять мелкими деталями с точностью сводит к минимуму риск повреждения и обеспечивает надежную сборку.

C. Фармацевтическая промышленность

Фармацевтическая промышленность использует питатели деталей для таких задач, как упаковка и выдача лекарств. Вибрационные питатели гарантируют операторам точную ориентацию и доставку таблеток и капсул, повышая эффективность и соответствие строгим отраслевым нормам.

V. Преимущества использования устройств подачи деталей

Устройства подачи деталей обладают рядом преимуществ, которые улучшают производственные процессы.

- Повышение эффективности и производительности: Автоматизируя обработку деталей, производители могут повысить производительность и сократить время цикла.

- Сокращение ручного труда и ошибок: Устройства подачи деталей сводят к минимуму необходимость ручного вмешательства, снижая вероятность ошибок и повышая безопасность.

- Последовательная ориентация и поставка деталей:Точность работы вибропитателей обеспечивает единообразную ориентацию деталей, что имеет решающее значение для автоматизированных процессов сборки.

VI. Выбор правильного производителя вибрационного питателя

При выборе производитель вибрационного питателя, вам следует учесть несколько факторов. Важно искать компании, которые предлагают индивидуальные решения, адаптированные под конкретные приложения. Кроме того, оценка опыта, репутации и услуг поддержки производителя может существенно повлиять на успех ваших усилий по автоматизации.

VII. Заключение

В заключение следует отметить, что питатели деталей, особенно вибрационные питатели и вибропитатели с чашей, являются важнейшими компонентами в области автоматизации. Их способность эффективно обрабатывать и ориентировать детали повышает производительность в различных отраслях промышленности, от автомобилестроения до фармацевтики. Поскольку производители продолжают внедрять автоматизацию, понимание роли питателей деталей становится все более важным. Выбор правильного производителя вибрационных питателей может иметь существенное значение для оптимизации производственных процессов и достижения желаемых результатов.

VIII. Часто задаваемые вопросы

Основная функция вибрационного питателя — автоматическая транспортировка и ориентация деталей, обеспечивающая правильную подачу для сборки или обработки.

Вибрационный питатель использует вибрацию и гравитацию для перемещения деталей внутри чашеобразного контейнера, сортируя и ориентируя их для последующих процессов.

Такие отрасли, как автомобилестроение, электроника и фармацевтика, широко используют устройства подачи деталей, где точная обработка и ориентация компонентов имеют решающее значение.

Да, конструкторы могут создать вибропитатели для бережной обработки хрупких деталей, сводя к минимуму риск повреждения во время транспортировки.

Чтобы выбрать правильный питатель деталей, рассмотрите такие факторы, как размер и форма деталей, требуемая скорость подачи и особые требования к обработке. Консультации с опытными производителями могут помочь определить лучшее решение.