Contorno

Visão geral dos alimentadores centrífugos e seu papel na fabricação.

Definição e comparação com outros alimentadores.

Estrutura de base, tigela, mecanismo de acionamento, trilho de alimentação e funil.

Etapas da operação: carga, aceleração, descarga.

Indústrias e usos específicos.

Eficiência, versatilidade, tempo de inatividade reduzido e precisão.

Fatores a serem considerados para seleção.

Problemas enfrentados e dicas de manutenção.

Inovações e avanços.

Perguntas frequentes sobre alimentadores centrífugos.

Introdução

Alimentadores centrífugos são vitais na fabricação moderna, manuseando e orientando peças de forma eficiente. Entender sua mecânica ajuda as empresas a escolher o equipamento certo para produtividade ideal.

O que é um alimentador centrífugo de peças?

Um alimentador centrífugo de peças usa força centrífuga para mover e orientar pequenos componentes, distinguindo-se dos alimentadores vibratórios. É ideal para alimentação de alta velocidade e orientação precisa de peças.

Para mais informações, leia este artigo: O que são alimentadores centrífugos

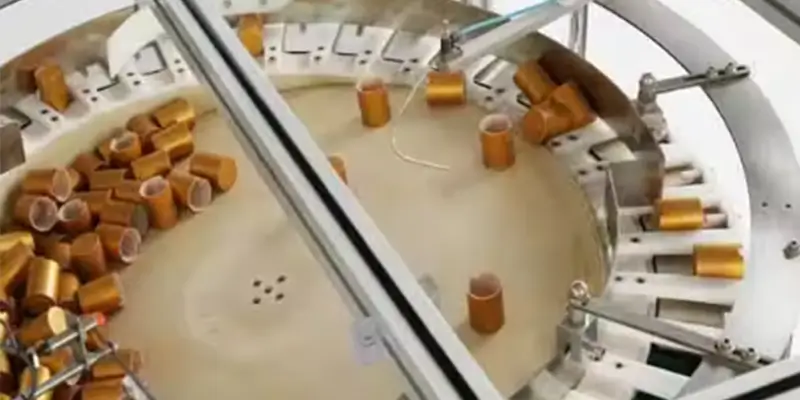

Principais componentes dos sistemas de alimentação centrífuga

Alimentadores centrífugos consistem em várias partes principais:

- Estrutura de base: Oferece estabilidade.

- Tigela: Acelera peças.

- Mecanismo de acionamento: Alimenta a rotação.

- Faixa de alimentação: Guia as peças para descarga.

- Funil: Armazena e alimenta peças na tigela.

Como funcionam os alimentadores centrífugos de tigela

A operação envolve três etapas:

- Carregamento: As peças entram na tigela.

- Aceleração: A força centrífuga move as peças para fora.

- Descarga: As peças orientadas saem da pista de alimentação.

Aplicações de sistemas de alimentação centrífuga

Esses alimentadores são usados em indústrias como automotiva, eletrônica e farmacêutica, manipulando uma variedade de pequenos componentes com eficiência.

Benefícios do uso de alimentadores centrífugos

As principais vantagens incluem:

- Operação de alta velocidade.

- Versatilidade para diferentes tipos de peças.

- Manutenção e tempo de inatividade reduzidos.

- Orientação consistente das peças.

Escolhendo o Alimentador de Peças Centrífugo Certo

Considere fatores como tamanho da peça, necessidades de aplicação e volume de produção para selecionar o alimentador mais adequado.

Desafios e soluções comuns

Problemas comuns incluem travamento e desgaste de peças. Manutenção regular e alinhamento adequado podem ajudar a reduzir esses desafios.

Tendências futuras em tecnologia de alimentação centrífuga

As tendências emergentes incluem maior automação, tecnologias inteligentes e foco na sustentabilidade em sistemas de alimentação.

Vídeo de combinação de alimentador centrífugo e embalagem de comprimidos

Perguntas frequentes

- Vantagens sobre alimentadores vibratórios?

Maiores velocidades e melhor orientação.

- Dicas de manutenção?

Inspeções e limpezas regulares.

- Compatibilidade de peças?

Personalizado de acordo com o formato e tamanho do material

- Opções de personalização?

Sim, ajustado às necessidades específicas.