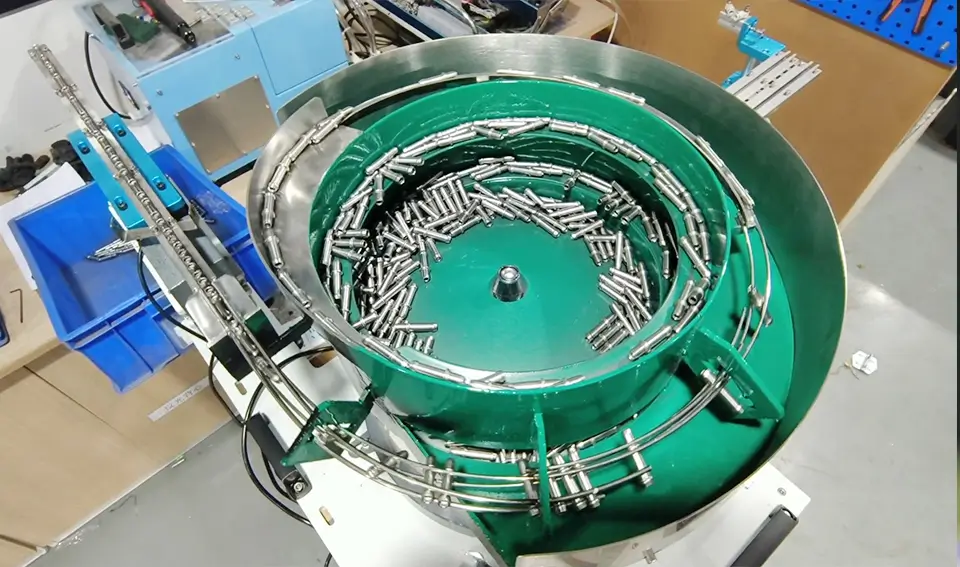

Manufacturing faucets, valves, and other bathroom hardware isn’t just about precision—it’s about efficiency too. That’s why more companies are turning to vibratory bowl feeders as a key part of their part feeding systems. These bowl feeding systems use controlled vibrations to sort, align, and transport faucet components automatically, eliminating bottlenecks and speeding up production.

Versatile Vibratory Parts Feeder for Complex Components

One of the biggest advantages of a vibratory parts feeder is its versatility. Whether you’re dealing with simple cylindrical pieces or irregularly shaped components, a well-designed vibratory bowl feeder design ensures each part is oriented correctly for seamless robotic picking. No more misaligned parts or production slowdowns—just smooth, automated feeding that keeps things moving.

Bowl Feeder Automation Enhances Manufacturing Flexibility

For manufacturers, bowl feeder automation does more than cut labor costs. It increases flexibility, making it easier to switch between different product lines, especially for small-batch or high-mix production. In today’s Industry 4.0 era, automation isn’t just an upgrade—it’s a necessity. Integrating a vibratory bowl feeder into your system means staying competitive with faster, smarter, and more reliable production.

Contato Swor

Entre em contato com a equipe da Swoer para um projeto personalizado de alimentador vibratório.